Our Engineering Process

Idea

The engineering process at CPI Automation begins with generating ideas and concepts for automation solutions. This stage involves brainstorming, research, and understanding the client's requirements and objectives. Engineers collaborate with clients to identify the automation needs and determine the feasibility of the project.

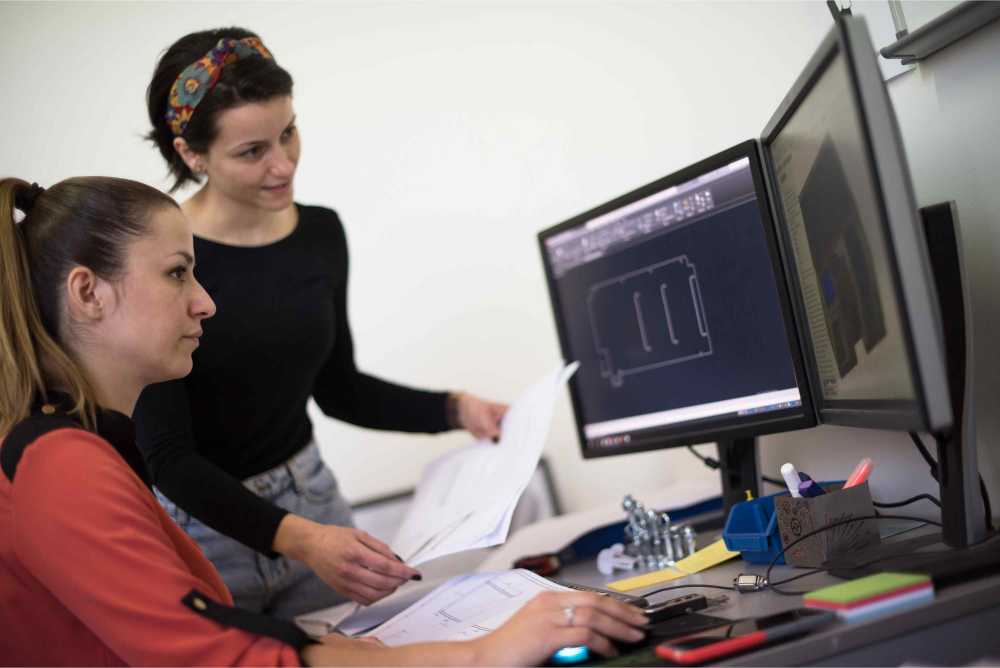

Designing

Once the idea is conceptualized, CPI Automation's engineers move on to the design phase. In this stage, they develop detailed plans and specifications for the automation system. This includes creating schematics, layouts, and 3D models to visualize the system. Designing also involves selecting appropriate components, software platforms, and technologies that align with the project requirements.

Sourcing

After the design is finalized, CPI Automation engineers initiate the sourcing process. They identify and procure the necessary components, equipment, and materials required for the automation system. This stage involves collaborating with suppliers, conducting price negotiations, ensuring quality standards, and managing the logistics of acquiring the required resources.

Build

Once all the required components and materials are sourced, CPI Automation moves on to the production phase. This stage involves assembling the automation system, integrating hardware and software components, and conducting thorough testing to ensure proper functionality. Engineers and technicians work together to build the automation solution according to the design specifications

Delivery

The final stage of CPI Automation's engineering process is the delivery of the completed automation system to the client. This involves packaging, transportation, and installation of the system at the client's site. Additionally, CPI Automation provides support for system setup, configuration, and initial operation. Engineers may conduct training sessions for the client's staff to ensure a smooth transition and effective utilization of the automation solution.